Gear Machining Process:

Blank → Heating (normalizing) → Gear cutting → Surface hardening (quenching, carburizing, nitriding etc.) → Finishing (grinding)

Blank → Heating (normalizing) → Gear cutting → Surface hardening (quenching, carburizing, nitriding etc.) → Finishing (grinding)

| Process | Typical Tooth/Surface Hardness | Core Toughness | Distortion Risk | Best For |

|---|---|---|---|---|

| Normalizing | HB 163–217 | High | Low | Large/low-load gears, pre-machining |

| Quenched & Tempered | HB 220–285 | Medium–High | Medium | General-purpose strength; small/medium gears |

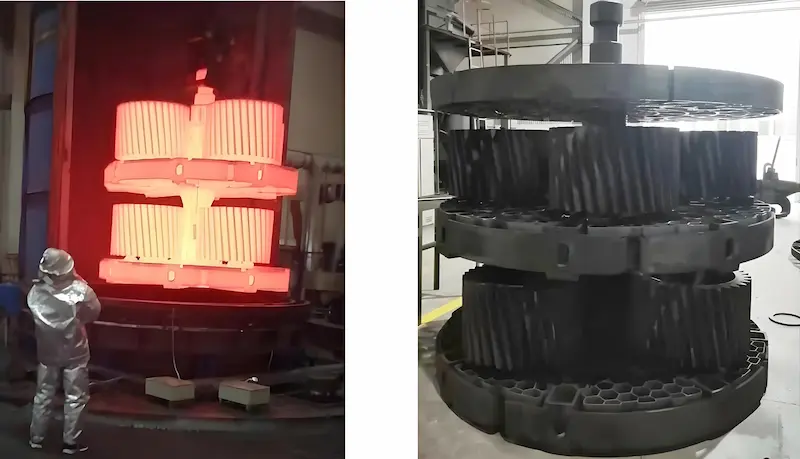

| Surface Hardening | HRC 45–55 (surface) | Tough core (pre-treated) | Medium | Impact load; higher surface wear |

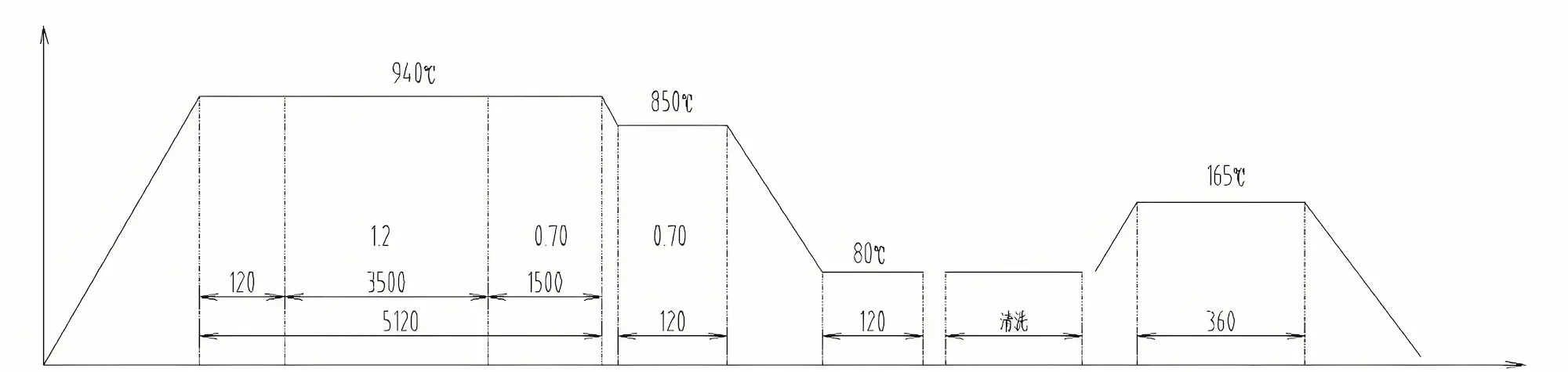

| Carburizing + Quench | HRC 58–63 (case) | Tough core | Higher (finish grind needed) | Heavy-duty / high load & shock |

| Ion Nitriding | High surface hardness (thin case) | Good (low-temp process) | Low | Precision parts; wear/corrosion resistance |