Bevel Gear, Custom Gear

Easy Guide to Bevel Gears

1. Introduction

Bevel gears are a cornerstone of modern power transmission systems. They enable torque and speed transfer between intersecting shafts, often at a 90° angle, making them indispensable in automotive differentials, agricultural tractors, heavy-duty trucks, industrial robots, and construction machinery.

According to Wikipedia, bevel gears have been used for centuries, but today’s requirements—higher loads, quieter operation, and greater durability—demand precision manufacturing.

Wenlio Gear, a subsidiary of PairGears LTD

Wenlio Gear focuses exclusively on bevel gears. Backed by 15+ years of gear-engineering heritage and a fully in-house production system—from forging and CNC machining to heat treatment and inspection—we deliver bevel solutions that OEMs trust worldwide.

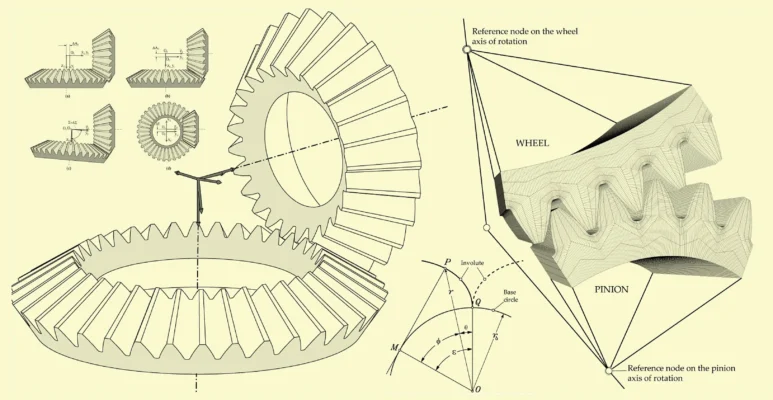

2. Types of Bevel Gears

2.1 Straight Bevel Gears

-

Design: Teeth are cut straight, radiating from the apex.

-

Advantages: Because the geometry is simple, they’re cost-effective and easy to manufacture.

-

Limitations: However, noise and vibration rise at higher speed.

-

Applications: So they fit hand tools, low-speed conveyors, and light machinery.

2.2 Spiral Bevel Gears

-

Design: Curved teeth create gradual, rolling contact.

-

Advantages: As a result, they run smoother, quieter, and carry higher load than straight bevels.

-

Applications: Therefore, they’re common in differentials for trucks, tractors, and EV drivetrains.

-

Wenlio Gear advantage: To keep performance consistent, Wenlio controls spiral bevel gears to DIN 6 precision for stable torque delivery.

2.3 Hypoid Gears

-

Design: The gear and pinion axes are offset.

-

Advantages: This offset supports very high torque transmission and typically quieter running, while also allowing a lower driveshaft position.

-

Applications: So hypoids are widely used in automotive rear axles, especially in heavy trucks and EVs.

2.4 Zerol Bevel Gears

-

Design: Zerol gears use a zero-degree spiral angle, so they sit between straight and spiral designs in behavior.

-

Applications: As a result, they suit precision machinery needing moderate load capacity and controlled smoothness.

2.5 Miter Bevel Gears

-

Design: A special bevel pair with the same tooth count, delivering a 1:1 ratio—typically at a 90° shaft angle.

-

Applications: Therefore, they’re used in hand drills, printing machines, conveyors, and light machinery where speed stays constant but direction changes.

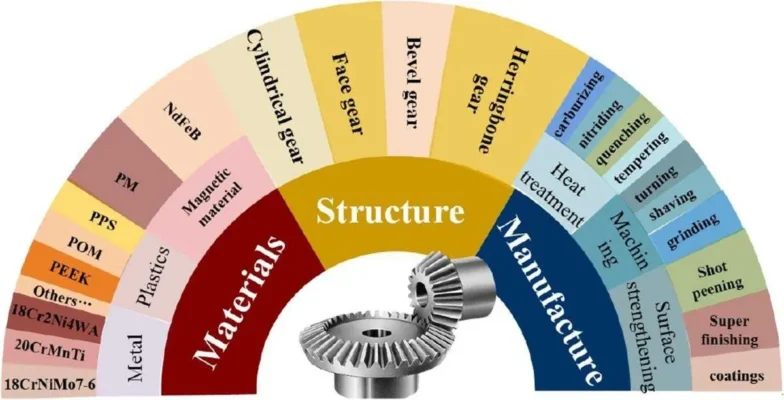

3. Design Considerations for Bevel Gears

3.1 Material Selection

• Alloy Steels (20CrMnTi, 18CrNiMo7-6): High strength and toughness.

• Case Hardening Steels: Improve wear resistance through carburizing and nitriding.

• SAE Standards: SAE 8620 is widely used for hypoid gears.

3.2 Tooth Geometry

Pressure angle, spiral angle, and face width determine load capacity.

Advanced design software ensures optimized tooth contact patterns, reducing noise and vibration.

3.3 Heat Treatment

• Carburizing: Increases surface hardness to 58–62 HRC.

• Nitriding: Improves wear and fatigue resistance.

• Induction Hardening: Used for selective surface strengthening.

4 . Applications Across Industries

4.1 Automotive Differentials

Bevel gears allow the left and right wheels to rotate at different speeds, essential for safe cornering.

4.2 Agricultural Machinery

Tractors, harvesters, and rotary tillers require gears with high torque resistance and long service life.

4.3 Heavy Trucks and Construction Equipment

For long-haul trucks and bulldozers, noise control and durability are critical.

4.4 Electric Vehicles and Robotics

EV drivetrains demand lightweight, low-noise gears, while industrial robots require compact, high-precision bevel gears.

5. Wenlio Gear Manufacturing Process

Forging – High-tonnage forging lines (1600T, 630T, 400T) produce defect-free blanks.

• CNC Machining – Multi-axis CNC centers achieve micron-level accuracy.

• Heat Treatment – Carburizing furnaces and nitriding lines extend gear life.

• Metrology – Gear measuring machines and CMM ensure compliance with international standards (AGMA 14, ISO Grade 6).

6. Why Choose Wenlio Gear?

• Precision: Gears manufactured to ISO 5 grade or better.

• Reliability: First-time assembly pass rate >98%.

• Flexibility: OEM customization, low MOQ, fast delivery.

• Global Reach: Products exported to Europe, North America, South America, and Southeast Asia.

7. Conclusion

Bevel gears may seem simple in appearance, but their performance determines the efficiency and reliability of entire machinery systems.Choosing the right bevel gear partner can define the reliability and performance of your entire machinery system. At Wenlio Gear, a dedicated sub-brand of PairGears, we combine precision engineering, strict quality control, and flexible OEM services to deliver gears that keep your business moving forward.

Contact us today to discuss your requirements: Get in Touch!